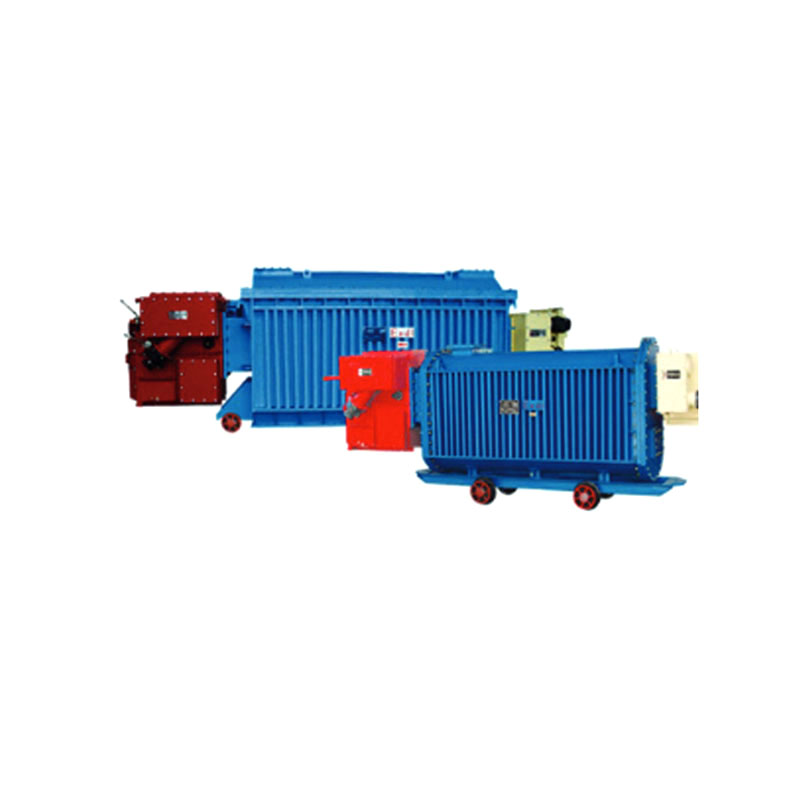

KBSG Mine Flameproof Dry Type Transformer KBSG

Purpose and Conditions of Use

This productisused inmines with methane mixed gas. coal dust and explosion risk as the powe distributiondevice ofcomprehensive mechanized mining equipment in coal mines.

Service conditions:Theproductcan work continuously for a long time under the following service conditions and rated capacity.

a.Altitude not exceeding 2000m;

b.The ambient temperature is not higher than +40 ℃;

c.The relative air humidity shall not exceed 95% (at+25℃);

d.Thereisnostrongturbulenceandvibrationandthe inclination of the vertical plane does not exceed 15 degrees;

e.There is no gas and steam that can corrode metal and damage insulation: f.A place without dripping water.

Structure Overview

Miningtameproofdrytypetranstormer KBSGis composed of box shell, box cover, iron core assembly,insulationassembly,high-voltagelead,low-voltage lead and trolley for railway track.

The transformer box shellisanexplosion-proof structure with top open cover. Four small hoisting mixers are setonthe boxcoverfor oistingduringtheremoval of the box cover. Corrugated steel plates are used onboth sidesofthe boxshellthickstee plates are used at the bottom of the box, and connectingflanges areset on the high and lowvoltage sides of the transformer to connect high and low voltaaeswitchesourarae hoistna mixersarearranaed on the box shell for the inteara hoisting of the transformer:Bothendsofthe boxshell are welded with grounding bolts and "=" grounding marks for connecting external grounding wires.

High andlowvoltageinterlockinglines and temperature control lines inside the transformer are respectivelyconnected with high andlowvoltage switches; PT100 platinum resistance or temperature relavisusedfortemperaturecontroWhenthetemperature in the transformer is too high. an ove temperature signal will be sent.

Transformer coreassemblyconsists ofcore,clipsinsulating parts and so on. The iron core adopts high-qualitycold-rolled oriented silicon steel sheet multi-stage stepping full-slope three-seam aminationstructuretoreducenooadossandnooad current: Hiah temperature anti-rust and moisture-proofpaint.Theclampis made of channe steel, and the upper and lower tension adopts the pul screwstructure.andmeasuresaretakento preventthe relative dispacement of the iron core and the clamp, so as not to affect theproductquality.The core insulation parts are made of domestic high-quality insulation materials.

Transformerinsulation assemblyincludes mainlongitudinal insulation. high and low voltage coils. coi pressingand otherstructures.Themainlongitudinal insulation is made of high-quality insulating materials High andlowvoltage coilsadopttight winding technology, which improves the mechanical strength o coils;HighandlowvoltagecoilsaremadeofC-grade insulating paper wrapped oxygen free copper conductors.The electric field aroundthe coils is uniform and the partial discharge is small. The coil shal be pressed with pressing nail and porcelain pressing block, and measures shall be taken to prevent looseness.

The high-voltagelead isled out by cableand thelow-voltage lead is led out by cable or copper bus. The creepagedistanceand airgap aregreater than the relevant provisions in GB3836.3-2000.Under normaloperatina condtionssparksarcsanddanaeroustemperatures will not occur. and the use is safe and reliable.

The trolleyisfixed atthebottom ofthe box with bolts and can be disassembled. The trolley gauge is900/600mm.

Contact with us